Application:

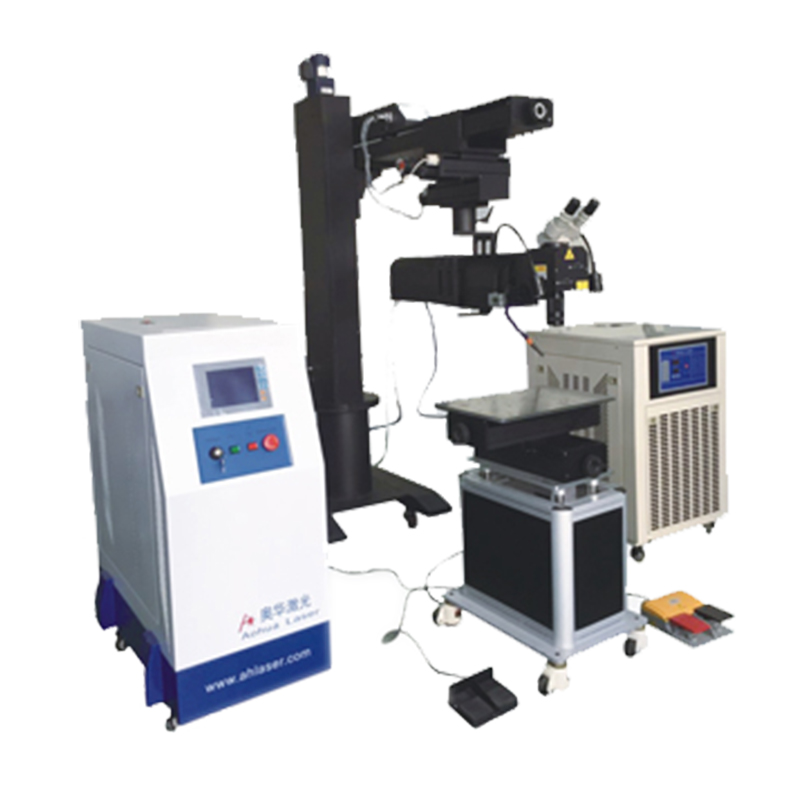

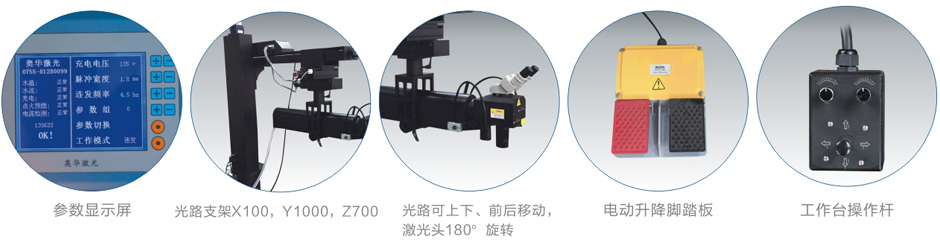

1. The optical path of laser can be electrically adjusted and controlled from ten directions without adopting the operation way of worktable which is mainly applied to the outsize large and medium-size mould repairing and the mould can be placed in carts forklifts or floor to conduct the repairing directly.

2. Mainly applicable to mold steel carbon steel alloy steel stainless steel beryllium copper copper alloy as well as such plastic mold casting mold forging die stamping mold die casting mould as with extremely hard alloy materials.

3. Widely used in mould manufacturing and molding industries such as mobile phones digital products automobile cars motorcycle mold making and mold industry.

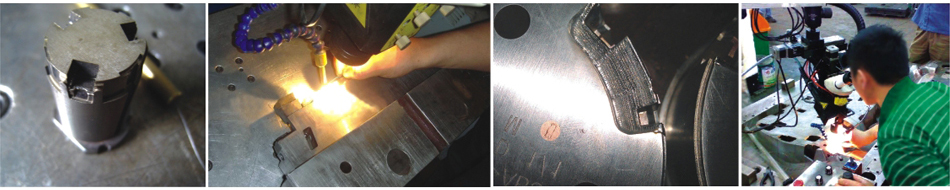

1. It fuses the special welding wire to the damaged parts of molds by hi-heat instantaneously generated by laser and thenfirmly fuses with the original substrate. After that it conducts the glossy processing through sparks and grinding in order to repair the mould.

2. It conducts the precision repair for the mold's blisters cracks chippings and wearing parts.

3. The area affected by heat is so small that can't cause the precision mould deformed.

4. Gas protecting system: synchronous argon protecting system controlled by micro-computer act better it make the welding connection even firmer and artistic. Being controlled to keep synchronous transmission with laser can save the argon at the highest level.

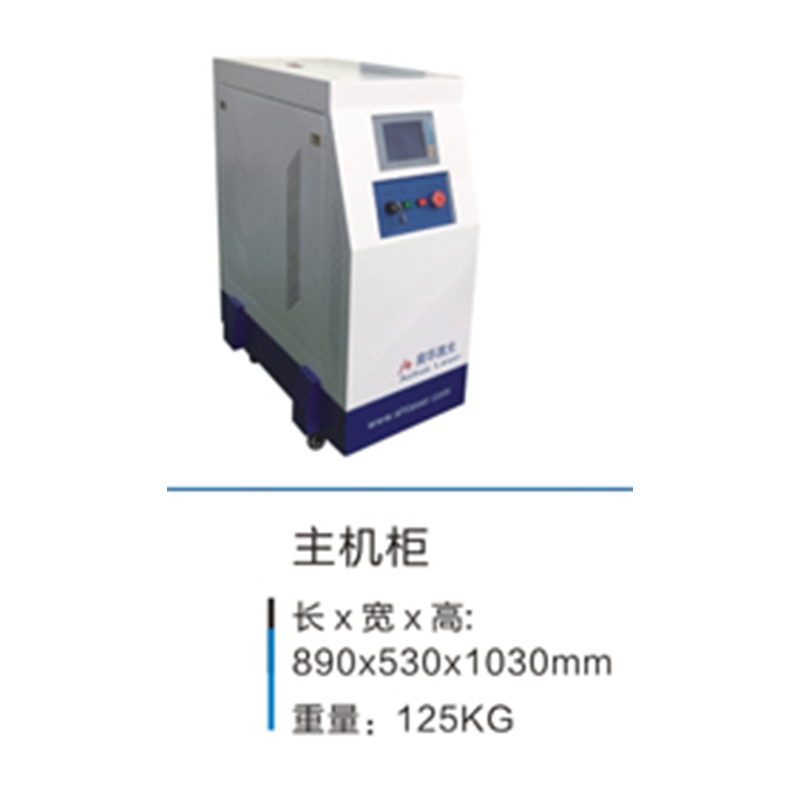

5. Laser controlling system can control the power source profile precisely pre-set optimized; under the control of double closed loop by inside improved industrial controlling micro-computer so the stability and the running ability surpass products that controlled by monolithic integrated circuit.

6. Observing system: equipped with special microscope observing system with cross cursor. It has high speed electron flitting device to protect the operator's eyes from being hurt.

7. Fully dissolved and no repairing trace and there is no depression phenomenon for the joint between convex fuse and substrate.

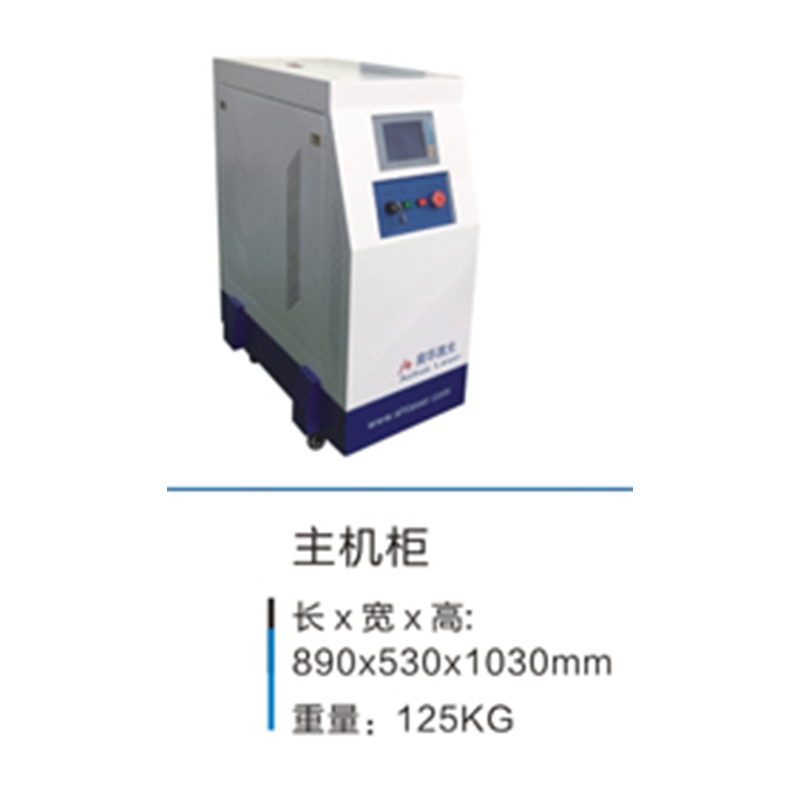

| Model | AHL-XBW220 | AHL-XBW400 |

| Max laser power | 220W | 400W |

| Laser wave length | 1064nm | 1064nm |

| Max monopulse power | 90J | 110J |

| Laser welding depth | 0.1-1.0mm | 0.1-1.0mm |

| Pulse width | 0.2-20ms | 0.2-20ms |

| Continuious welding frequency | 0.5-20Hz | 0.5-20Hz |

| Facula size adjustable range | 0.2-2mm | 0.2-2mm |

| Laser welding stick | φ0.2-φ0.5mm | φ0.2-φ0.5mm |

| Power consumption | ≤7KW | ≤12KW |

| Power demand | 220V±10%/50Hz/40A(380V) | 380V±10%/50Hz/40A |

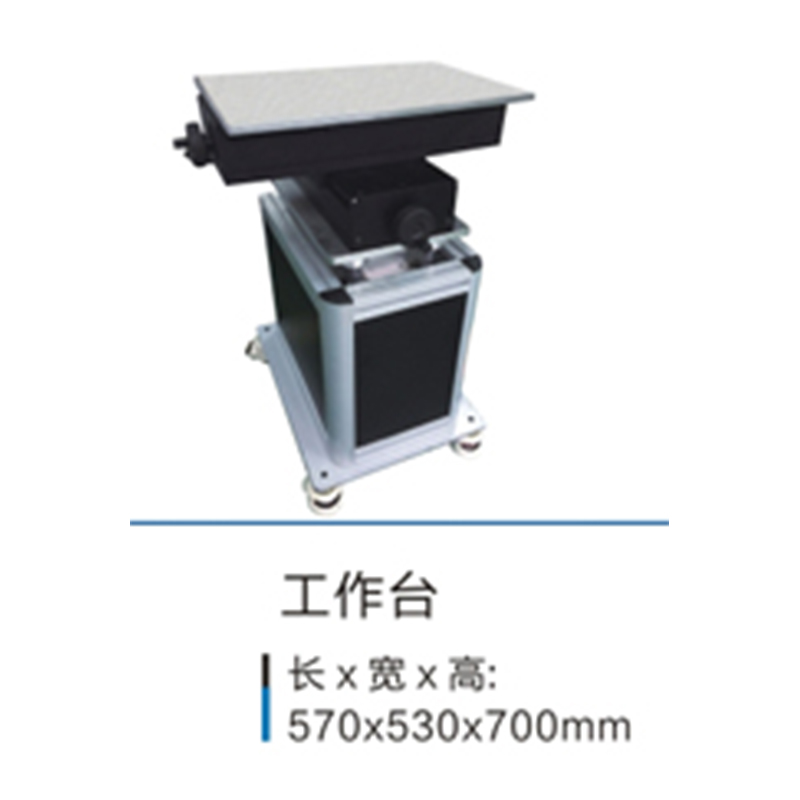

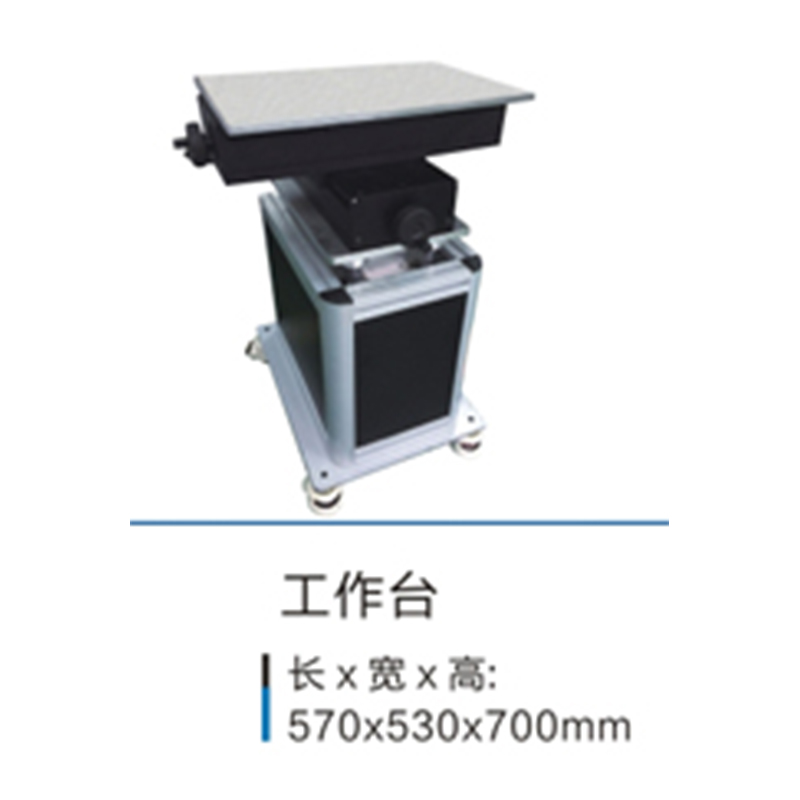

| Worktable | 3D manual | 3D manual |

| Positioning | Microscope | Microscope |

| Laser | 300mm | 300mm |

| Laser axial direction | 360° | 360° |

| Laser horizontal direction | Y axis/XY Electric | Y axis/XY Electric |