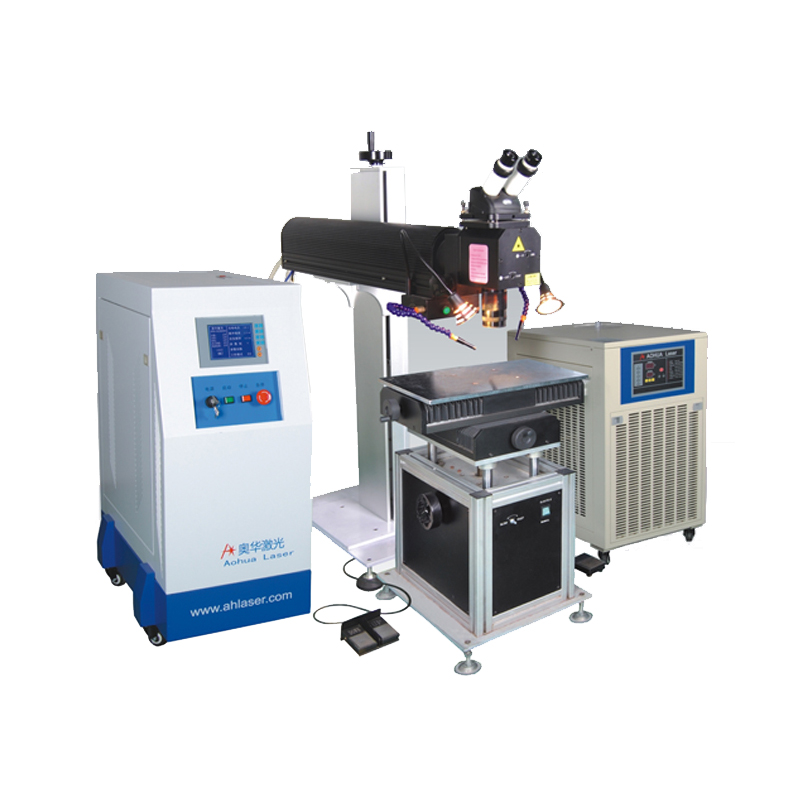

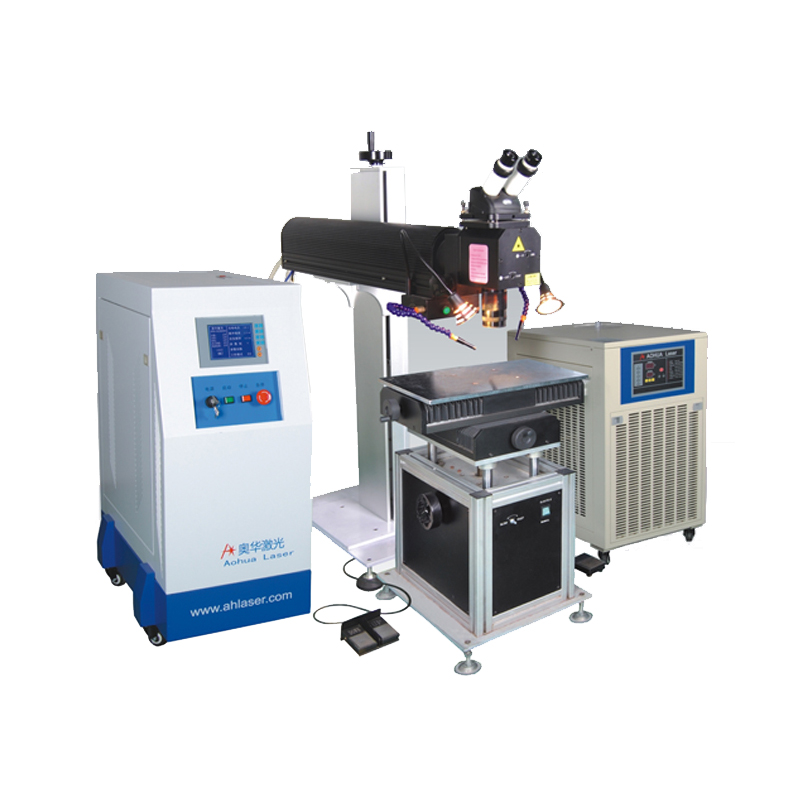

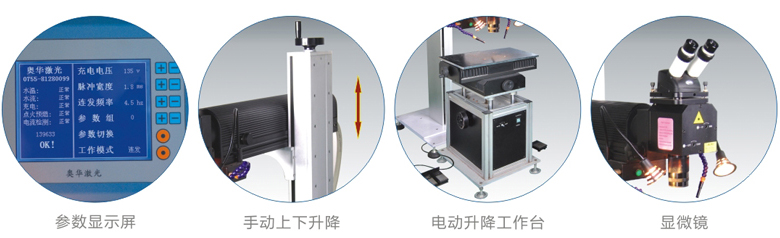

1. AHL-W220III/400III laser mold welding machine is the third generation laser mold repair equipment developed by Aohua. The laser can be moved up and down, back and forth, and the worktable can be operated electrically up and down. It is mainly used for large,

Medium-sized mold repair.

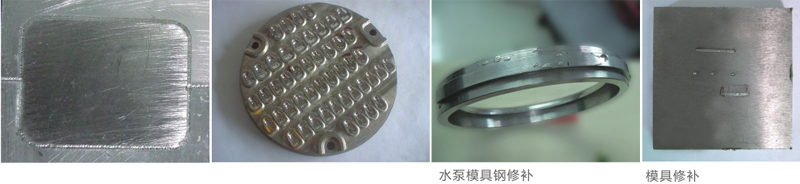

2. Mainly used for S136, SKD-11, NAK80, 8407, 718, 738, H13, P20, W302, 2344 and other die steel, carbon steel, ordinary alloy steel, stainless steel, beryllium copper, copper and

Plastic molds, casting molds, forging molds, stamping molds, die-casting molds, etc. of extremely hard alloy materials.

3. Widely used in mold manufacturing and molding industries such as mobile phones, digital products, automobiles and motorcycles.

1. The laser mold welding machine (manual laser welding machine) uses the high heat generated by the laser to weld the special welding wire to the damaged part of the mold, and the original base material is firmly welded. After welding, it is processed by electric spark, grinding, etc. Smooth surface to repair the mold.

2. Precise repair of small parts such as mold blisters, cracks, chipping, and wear.

3. The heat-affected area is small and will not cause deformation of the precision mold.

4. The welding depth is large, which is firm and beautiful.

5. Full melting, leaving no repair traces, and no depression in the joint between the raised part of the molten material in the melting pool and the substrate.

| Model | AHL-W220III | AHL-W400III |

| Max laser power | 220W | 400W |

| Laser wavelength | 1064nm | 1064nm |

| Max monopulse power | 90J | 110J |

| Laser welding depth | 0.1-0.8mm | 0.1-1.0mm |

| Pulse width | 0.2-20ms | 0.2-20ms |

| Continuous laser welding frequency | 0.5-20Hz | 0.5-20Hz |

| Adjustable range of spot size | 0.2-2mm | 0.2-2mm |

| Laser welding wire | φ0.2-φ0.4mm | φ0.2-φ0.5mm |

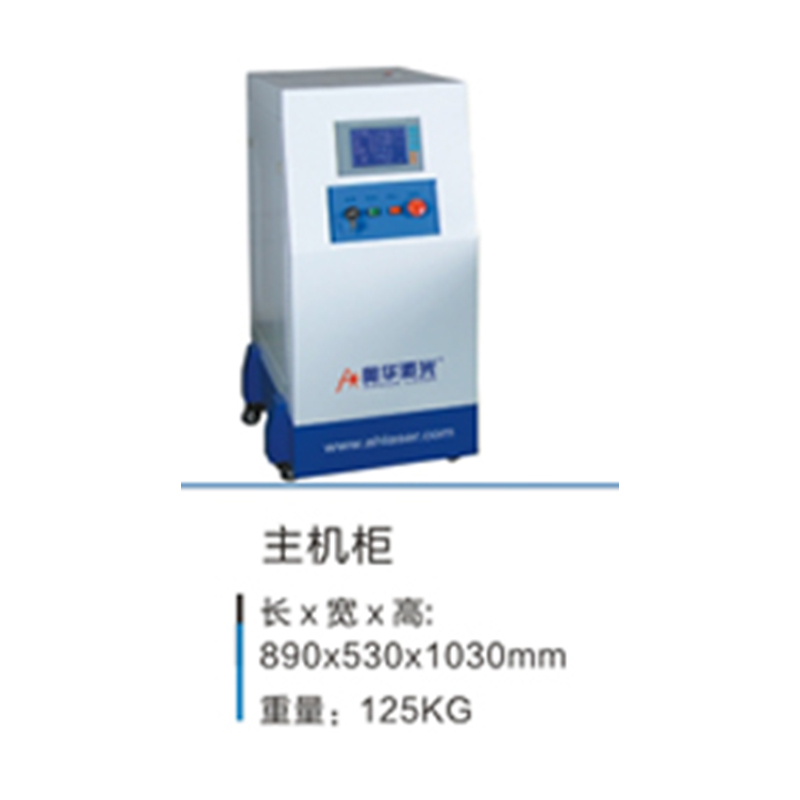

| Total power | ≤7KW | ≤12KW |

| Electricity demand | 220V±10%/50Hz/40A(380V) | 380V±10%/50Hz/40A |

| Standard worktable | 3D manual | 3D manual |

| Positioning | Microscope | Microscope |

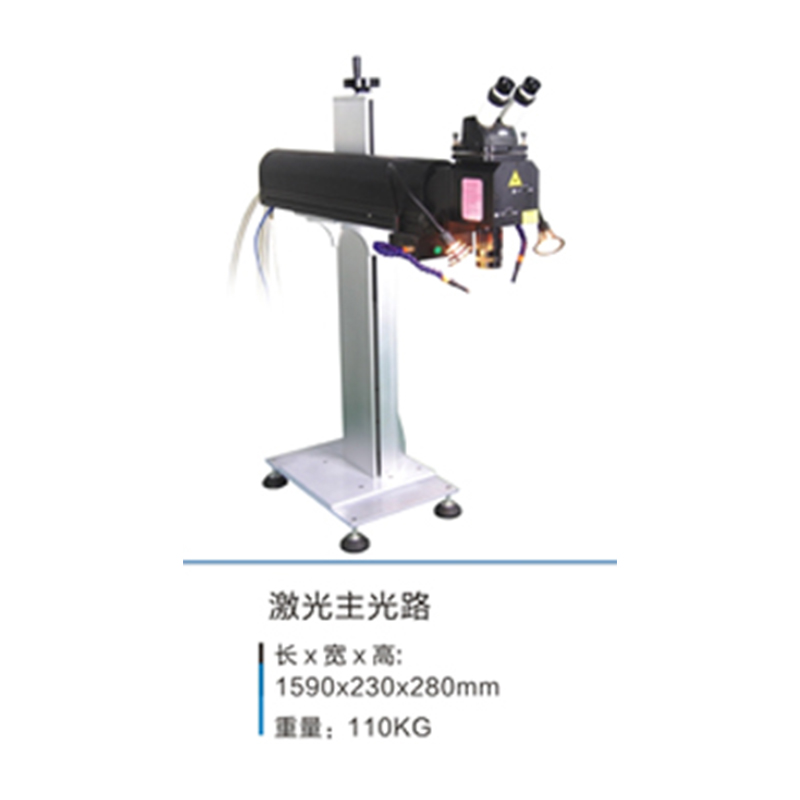

| Up and down stroke of laser | Fixed/300mm | Fixed/300mm |

| Laser axis rotation | Fixed | Fixed |

| Laser horizontal direction | Fixed | Fixed |