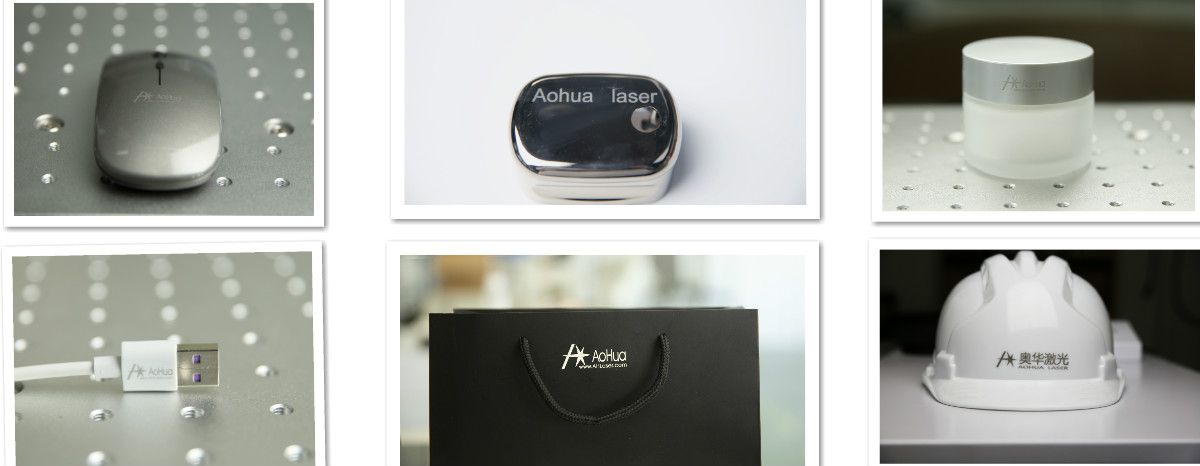

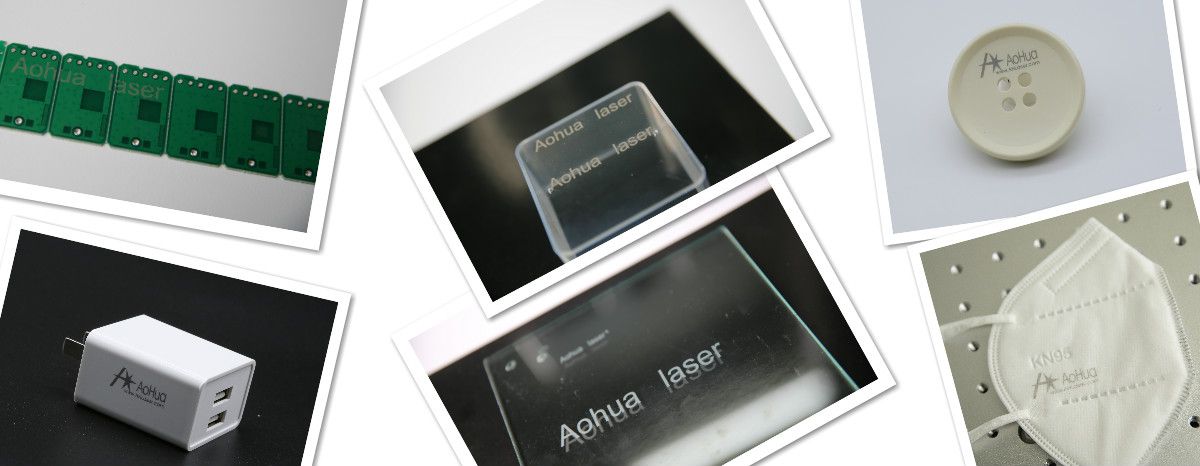

1. UV laser marking machine is mainly used in the high-end market of ultra-fine processing. It is used for marking the surface of packaging bottles of drugs, cosmetics, videos and other polymer materials. The effect is very fine and the marks are cleaned firmly,It is better than ink jet printing and pollution-free.

2. Marking and dicing of flexible PCB board; processing of micro hole and blind hole of silicon wafer;

3. LCD two-dimensional code marking, glass surface drilling, metal surface coating marking, plastic keys, electronic components, gifts, communication equipment, building materials, etc.

1. The beam quality is high, the spot is very small, it can realize super fine marking and special material marking;

2. Almost perfect marking quality: 355nm output wavelength reduces the thermal impact on the workpiece;

3. The marking effect is fine and can be processed repeatedly; high precision and fine spot ensure the perfect marking result;

4. The marking process is non-contact and the marking effect is permanent;

5. The heat affected area is very small, the result of marking and cutting is precise and smooth, the side wall is steep and straight, there is no thermal effect, the material is not deformed and does not burn;

6. It is suitable for processing materials with high thermal radiation reaction;

7. Suitable for processing materials with thermal radiation reaction;

8. It can cooperate with the production line, automatically loading and unloading, automatic feeding and discharging; it is suitable for marking on most metal and non-metallic materials.

9. Ultraviolet laser except copper material, many materials absorb 355 nm ultraviolet light, so UV laser can be suitable for processing more types of materials.

| Maxmum laser power | 3/5/8W |

| Repeated laser frequency | 10-50KHZ |

| Minimum adjustable Q laser pulse width | 30ns |

| Laser wave length | 355nm |

| Optical quality | ㎡<1.2 |

| Beam divergence angle | <0.3mrad |

| Range for standard curve | 50*50 100*100 |

| Craving wicking | 12000mm/s |

| Minimum line width | 0.01mm |

| Repeated accuracy | ±0.003mm |

| Power demand | 220V±22V/50Hz/15A |

| Total electric consumption | 4KW |

| Working temperature | 15-30°C |

| Compared humidity | < 80% |

| Cooling method | Water-cooling |

Previous:360 degree rotatable fiber laser marking machine

Next:No data